The importance of the size of the beads to be selected

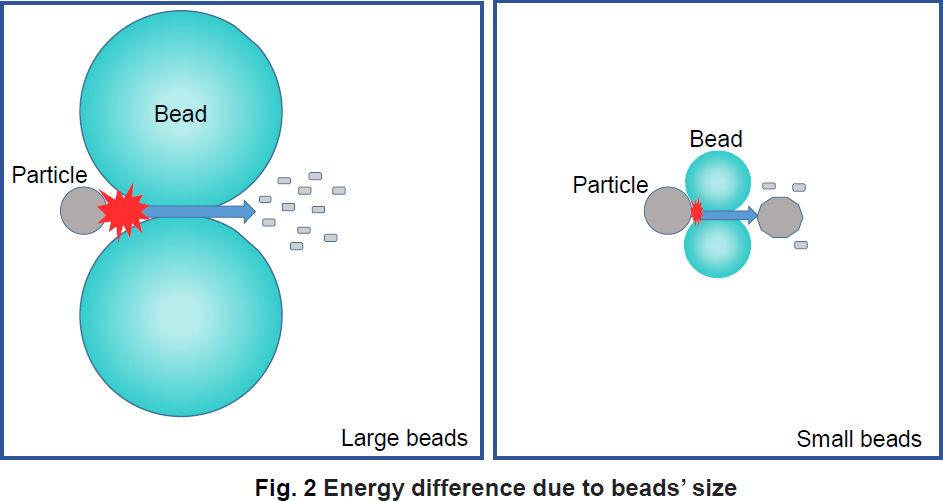

The bead size is the most important factor for milling practices. Large beads, bigger than 0.5 mm, are adequate for grinding micron-size particles into submicron-size ones. Small beads, 0.3 mm or finer, are applied to grinding or dispersing submicron- or nanometer-size particles. For dispersing, a large impact is not necessarily required, and, in addition, smaller beads provide faster processing rates since frequency of contact between a bead and a particle increases. In particular: 1) The adequate impact energy for milling, which is controlled by the bead size, rotor speed, and mass of the beads charged in the mill, is determined according to the target size and hardness of the particles. 2) The frequency of the impact between a bead and a particle, which is controlled by the rotor speed and bead size, affects the processing rate.

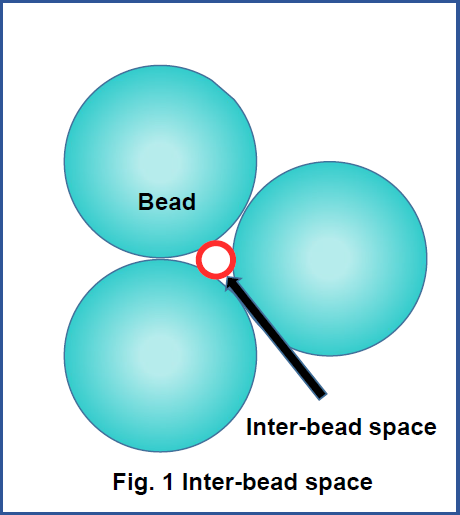

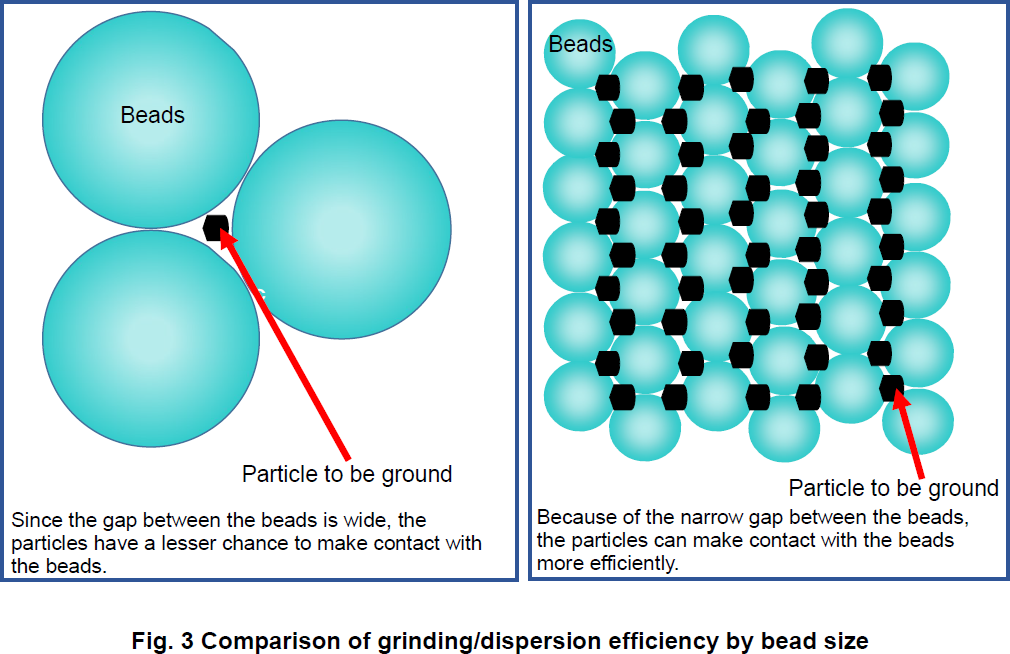

3) The inter-bead space affects the final size of particles after milling. The size of the inter-bead space is proportional to that of beads, so that smaller beads provide more chances for contacting the finer particles. Note that the inter-bead space is the space surrounded by beads when beads are closely packed (see Fig. 1).

Bead selection in grinding processing

In case of grinding large or hard particles, it is necessary to apply high impact energy to the particles. Since the intensity of energy is determined by the mass and speed of beads, large beads with a high speed are needed for grinding large and/or hard particles. When grinding hard particles, such as silica, alumina, and hard natural ores, relatively large beads—larger than 0.3 mm—are used as a grinding medium.

However, large beads are not always suitable for grinding processing. The size of the beads affects the final size of the particles. In case of grinding minute particles, as of 200 nm or finer, beads of the size of 0.1 or 0.3 mm are applied for grinding processing.

In addition, smaller beads shorten the processing time because their wider surface area increases the frequency of impact between beads and particles. Accordingly, if the particles are soft and then the required impact energy is low, milling with smaller beads results in a faster processing rate. Examples of such soft particles are calcium carbonate, iron oxide, agrochemicals, and pharmaceutical chemicals. In case of grinding fine particles of the size of 200 nm or smaller, the selection of beads’ size is quite important. Since the inter-bead space among larger beads is larger, opportunities for the particles to come into contact with the beads are fewer, resulting in poor grinding efficiency. Therefore, processing practice using small beads is required for grinding fine particles.

The size of the beads required for milling particles is 10 to 30 times the maximum particle size of the raw material and 1,000 to 3,000 times the mean particle size after milling. For example, when grinding calcium carbonate of 10 μm as the largest size of raw material to final-size particles of 100 nm, it is recommended to use 0.1 mm beads.

Bead selection in dispersing processing

The basic idea of selecting bead size for dispersing processing is similar to that for grinding processing. Some other conditions being considered are, however, different. The most important among them is the damage on primary particles by the impact of beads. The impact energy required for dispersion is controlled so as not to damage the primary particles and, at the same time, be enough to tear a cluster into primary particles.

Since each particle is made in the intended size that provides appropriate properties designed for the final products, damage on the particles is not desirable. In addition, in case that the impact energy is too high, primary particles get damaged and fine fractions are generated. The fine fractions act as a binder for re-agglomeration of the particles, so that dispersion is not completed even by a long time processing. The impact energy is, therefore, controlled not too intense and not too weak. Applying low-impact energy through small beads is, therefore, important for dispersing processing for obtaining lowly damaged nanoparticles. In addition, small beads provide high frequency of impacts between the particle and the bead, resulting in a high processing rate.

Generally, it is necessary to select smaller beads in dispersion processing as the primary particles become smaller. Desirable bead size is also 1,000 to 2,000 times the primary particles’. In many cases of modern dispersing practices, the primary particle is mainly 10 to 200 nm in size, so that the bead size to be selected is generally smaller than that for grinding processing. For example, when the primary particle is 100 nm in size, beads of 100 μm or finer are commonly selected. Primary particles that have been recently processed for modern nanomaterials are 50 nm or finer in size.