Zirconium bead grinding drug: the process of preparing magnesium aluminate drug nanocrystals by wet nano grinding technology

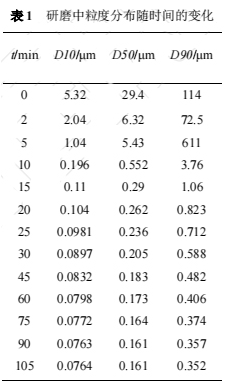

Magnesium aluminate is an effective drug for the treatment of gastropathy. Its nano particle suspension has better anti acid effect and faster onset. In this paper, sodium hexametaphosphate was selected as dispersant, and the effects of dispersant dosage, grinding speed, magnesium aluminate content and grinding time on particle size distribution were investigated by using a wet grinding machine. The optimum process operating conditions were obtained as follows: grinding speed 3000r / min, grinding time 105 minutes, main drug volume fraction 2%, When the dispersant was 1.5% of the mass fraction of solid content, nano suspensions of magnesium aluminate with particle sizes of d10 (76.4 nm), D50 (161 nm) and D90 (352 nm) were successfully obtained. The results of acid making force experiment show that the dissolution rate of nano magnesium aluminate suspension is more than 5 times faster than that of micron suspension in hydrochloric acid.

The preparation of drug nanocrystals by wet grinding is a complex pharmaceutical process. The grinder is usually pre filled with 50% ~ 75% (volume fraction) Zeno zirconia beads, and the size range of zirconia beads is usually 0.1 ~ 4mm. In the solution, the high-speed grinding medium and API particles squeeze and collide with each other, and the stress applied by the grinding medium is concentrated on the API particles, resulting in crack propagation and fracture of the particles, and then the particles are broken and smaller. It is found that in nano wet grinding, the particle breakage rate increases with the increase of the stress applied to the particles and decreases with the increase of the particle strength.

At the speed of up to several thousand revolutions per minute, the centrifugal acceleration will be 700 times that of gravity. At this time, the grinding medium has a high energy density and can effectively break API particles. Therefore, the wet grinding efficiency is very high. However, when the particle size is broken to the nanometer level, the broken fine particles are prone to agglomeration and recrystallization, and even crystal form conversion, which makes it difficult to accurately control the particle size distribution, and the product quality varies greatly between batches. In practice, it is often found that the particle size will not change after grinding to 500 ~ 600nm, so it is difficult to obtain particle products below 200nm.

Some studies found that nano-sized API particles were prepared by grinding with multistage nano wet grinding mill by adding additives such as space stabilizer and surfactant. It is found that the grinding time will affect the particle size of suspension particles. However, the longer the grinding time, the greater the energy required. The experimental conditions are as follows: the initial solid mass fraction of magnesium aluminate suspension is 2%, the mass of dispersant is 1.5% of the mass of magnesium aluminate, the rotating speed of grinder is 3000r / min, and the particle size distribution of suspension is analyzed by intermittent sampling.

Fig. 6 and table 1 show the trend of the average particle size of suspension drug particles with time under the experimental conditions. It is found that within 10 minutes after grinding, the particle size of API particles in suspension changes very quickly with grinding time. After grinding for 15 minutes, the reduction rate of API particle size slows down, and the particle size distribution diagram obviously shows curve superposition. Fig. 6 also shows the cumulative particle size distribution results of samples taken at different grinding times. It can be found that the particle size change trend gradually decreases with the increase of grinding time. Analysis of Table 1 shows that the average particle size is 29.4 μ After grinding for 15min, the average particle size of API raw materials reaches d500.29 μ m、D901.06 μ m。 After grinding for 20min, it can be observed that the particle size decreases slowly. After grinding for 90min, the particle size basically does not change. The particle size of suspension: D10 is 0.0763 μ m. D50 is 0.161 μ m. D90 is 0.357 μ m。 Considering the reduction of energy and equipment loss, the grinding end time can be selected between 20-90min.